Manufacturing

Manufacturing Procedures:

Equipment

- Striebig has established itself as the epitome of quality in vertical panel saws. These Swiss-engineered saws are produced by a company dedicated solely to vertical panel saws for over five decades. The precision, squareness, quality of cut, and durability offered by Striebig’s equipment are key factors that make it the choice for our facility.

- To ensure uniformity, we’ve designed and produced our hydraulic press, allowing for custom adapters to evenly press all our wood pads.

- In our equipment arsenal, top-notch edge sanders play a crucial role, contributing to the smooth and durable finish of our products.

Process

- Every layer’s surface is fully glued, ensuring a complete bond. Following assembly, each pad undergoes hydraulic pressing according to our specifications. If requested by the client, a water seal and mold inhibitor are applied at this stage.

Production Volumes and Lead times

- Our most significant competitive advantage lies in our unparalleled manufacturing lead times, ensuring swift delivery of our products to our clients.

- All equipment in our facility is strategically positioned to efficiently manage our clients’ production volumes.

Manufacturing Procedures:

Equipment

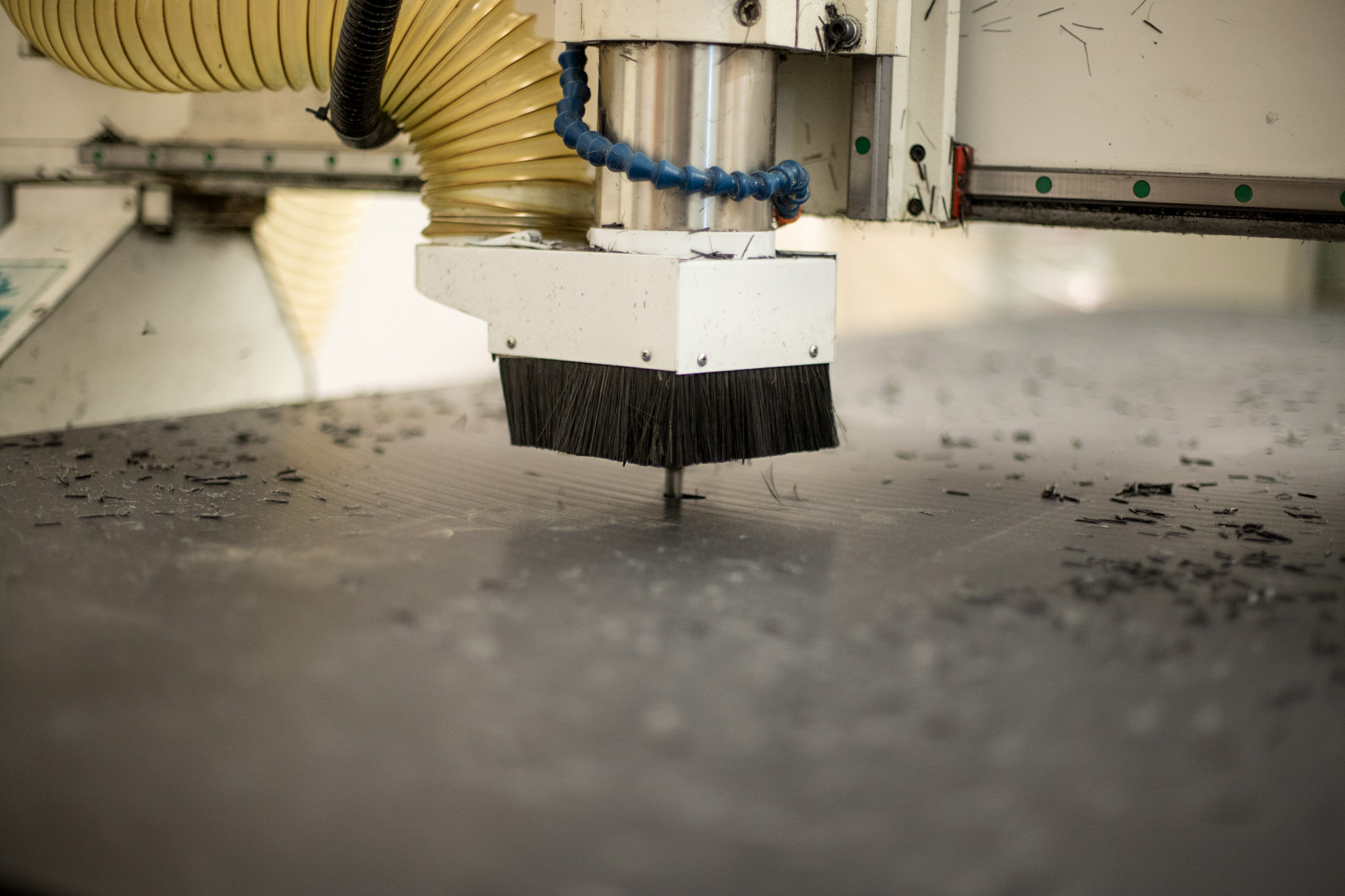

- We utilize custom-built CNC router machines from Europe, designed to meet our precise manufacturing specifications for the production of UHMW composite pads.

Process

- Each UHMW composite pad is accompanied by its own engineered drawing, which is utilized in our manufacturing process.

Production Volumes and Lead times

- Our primary competitive advantage lies in our unparalleled manufacturing lead times, ensuring prompt delivery of our products to clients.

- All equipment within our facility is strategically positioned to efficiently manage our clients’ production volumes.

Manufacturing Procedures:

Equipment

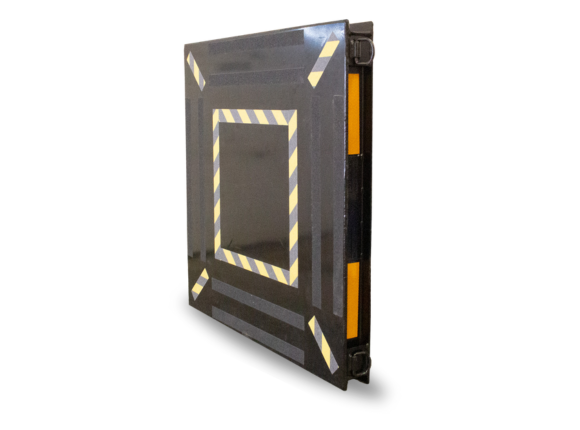

- Our high-quality Steel Crane Pads are meticulously crafted with the level of detail our clients have grown accustomed to. Each pad is manufactured, welded, and fabricated by skilled red seal welders. Our engineer-stamped and approved certification stands out as a key differentiator from our competitors. Additionally, our competitive pricing and efficient manufacturing lead times are managed within a state-of-the-art facility.

Each of our engineered steel crane pad

- Are fully internally and externally inspected throughout its manufactured process and do not flex with time.

- Come with 3M safety-walk, a nonslip top surface finish that is durable and long-lasting.

- Have an identification plate which contains load capacity specifications and trackable serial number.

- Are unaffected by chemicals and water. Rest assured, our crane pads won’t rust or degrade in any way. Our steel crane pads go through a high quality, durable powder coating process.

- Are equipped with 4 heavy duty D-Rings to facilitate lifting.

Production Volumes and Lead times

- Our biggest competitive edge is our unmatched manufacturing lead times to get our products in the hands of our clients.

- All of our pieces of equipment in our facility are strategically placed to handle our client’s production volumes in the most efficient way.